Cell Sorters

- Home

- Cell Sorters

- SH800S Cell Sorter

SH800S Cell Sorter

Overview

Sorting Made Simple™

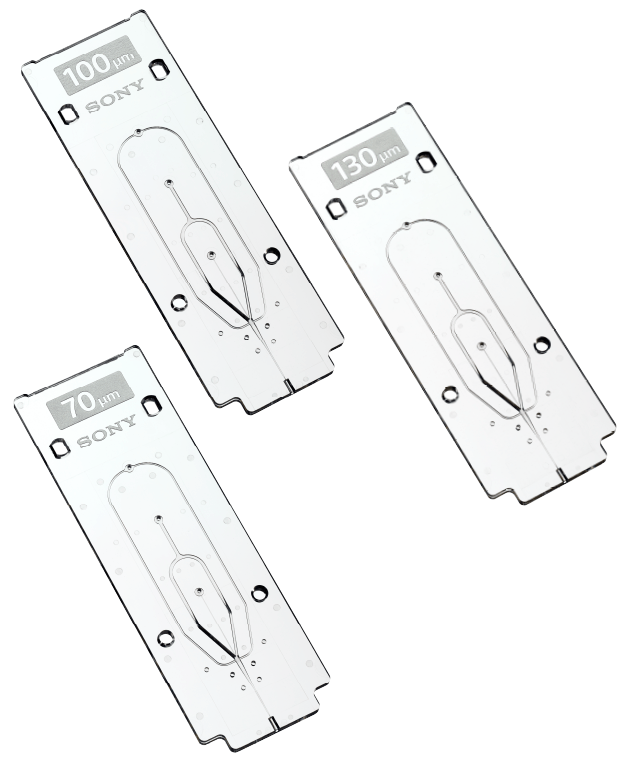

The benchtop SH800S cell sorter permits sorting of a wide range of cell sizes for many applications using the 70-μm, 100-μm, and 130-μm microfluidic sorting chips. This novel, chip-based design is fully integrated with comprehensive fluidics controls and advanced automation for set-up, acquisition, sort and analysis to make sorting less subjective, more precise and easier to perform.

System software is intuitive and supports sorting into tubes and 96- and 384-well plates. The software generates FCS 3.0 and FCS 3.1 files that can be exported to third party analysis tools.

The SH800S is flexible and can support a variety of applications for individual and core labs. For applications in which cross-contamination is a concern, optional e-beam sterilized consumables can be used to replace the sample line and sorting chip.

An optional class A2 Level II biosafety cabinet provides protection for personnel and products. The biosafety cabinet was custom designed for the SH800S and tested by The Baker Company to meet international standards.

The optical design offers up to four collinear excitation lasers (488 nm, 405nm, 561nm and 638nm) and six fluorescence detectors. The six free-form PMTs enable detection of fluorescence signals from any laser based on filter selection.

SH800S Cell Sorter Highlights

- Provides the highest level of automation available in any cell sorter, allowing researcher set-up, alignment, calibration and monitoring with a push of a button.

- A novel microfluidic sorting chip is available in three sizes including 70 μm, 100 μm, and 130 μm to permit sorting of a wide range of cell sizes which simplifies sorting.

- An optional custom biosafety cabinet meets industry standards for personnel and product protection.

For Research Use Only.

Class 1 Laser Product.

System

Automation from Set-up to Analysis

The SH800S provides the highest level of automation and ease of use available in a cell sorter. Researchers can accurately set up, calibrate, and monitor sorting with a push of a button. This delivers true ease of operation to save time and improve consistency of results.

A novel microfluidic sorting chip uses patented CoreFinder™ technology to automate key steps of instrument setup and operation, streamlining workflow.

The system is versatile, allowing researchers to sort of a wide range of cell sizes to accommodate application requirements. Chip sizes include 70 μm, 100 μm, and 130 μm.

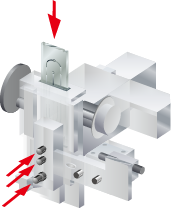

Automated Chip Loading and Positioning

System set-up begins with a one-touch install to load the microfluidics flow cell chip. Actuators ensure precise positioning of the chip inside the chip loader. Sheath, sample, and vacuum lines connect and seal automatically to their respective ports once the chip is loaded. Made of durable plastic, the chip is easy to replace when needed.

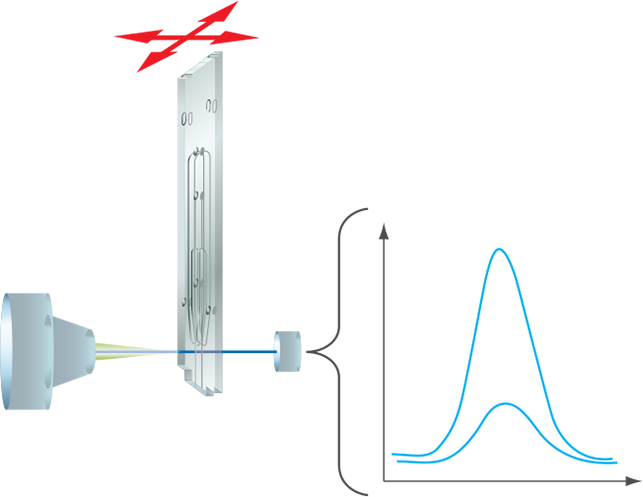

Automated Optical Axis Adjustment

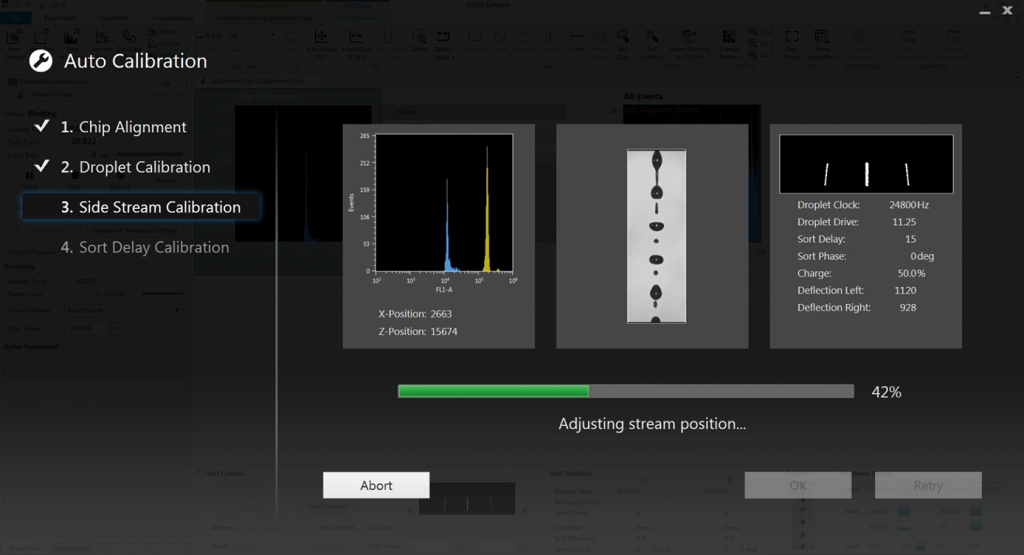

The alignment of the chip to the lasers is optimized automatically during setup using the Sony patented Blu-ray™ technology for aligning and tracking laser position. On a daily basis, using AutoSetup beads, the X and Z positions of the chip are adjusted to ensure consistent results.

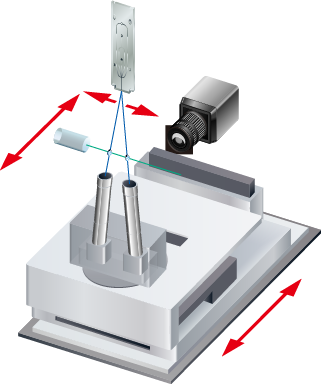

Automated Side Stream Calibration

The angle and the position of the side streams are calculated and adjusted during setup for tube and plate sorting. This ensures that the sort stream is centered in the collection tube automatically without manual adjustment.

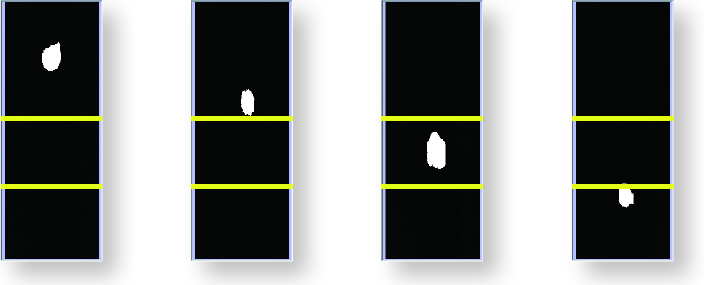

Automated Drop Delay Calibration

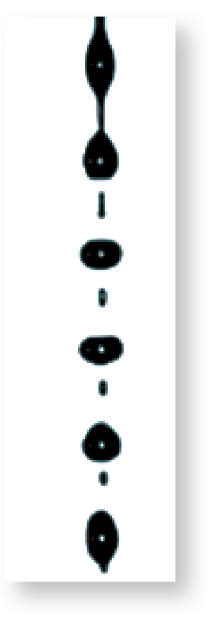

A dedicated laser and camera perform real-time analysis of droplet images using AutoSetup beads. Patented technology calculates drop delay by capturing the fluorescence image of the drop-delay beads. The relationship between bead posiitions and drop delay is used to calculate the optimal drop-delay to enable precise targeting and high yield. Automatic analysis of the binary image of the droplets, in real time, calculates the drop delay using a patented algorithm.

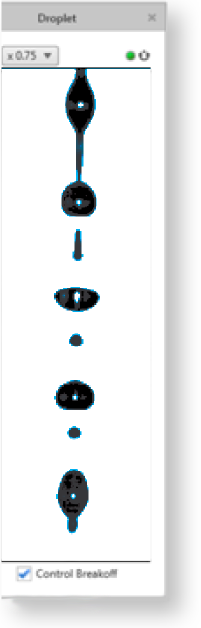

Automated Sort Monitoring and Droplet Calibration

The SH800S software monitors and actively makes adjustments to the drop drive to maintain a stable breakoff point. This feature ensures consistently good sort performance and allows detection of clogs and empty tubes, and facilitates walk-away operation.

The droplets are automatically calibrated by adjusting the frequency and the drop drive to achieve optimal break off point (BOP) for each type of sorting chip.

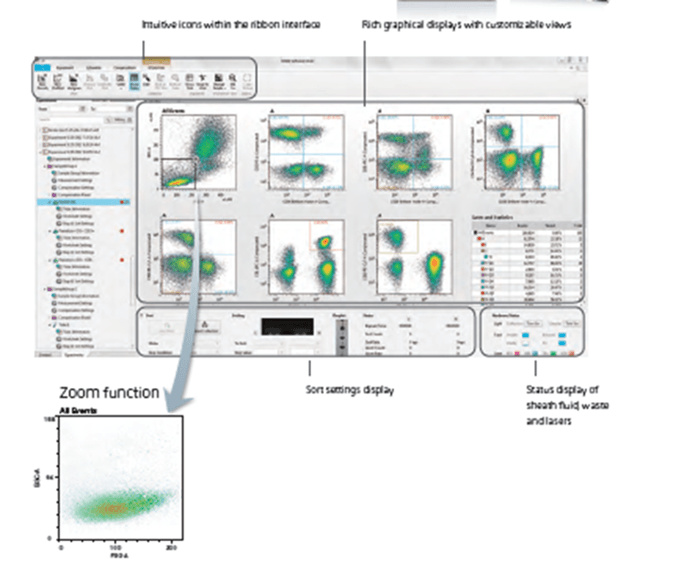

Software

Software, sensors, and CoreFinder patented technology provide automation across the workflow from set-up to shutdown to ensure consistency, save time and improve the accuracy of results. The interface is designed with ribbon tabs that logically organize features to make them rapidly accessible. An experiment-centric approach makes the software easy to teach, learn, and use.

Software wizards include step-wise workflows that guide users through start up, multicolor compensation, sorting, and system cleaning. Since the system simplifies even advanced sorting techniques, it can be used by researchers with little sorting experience.

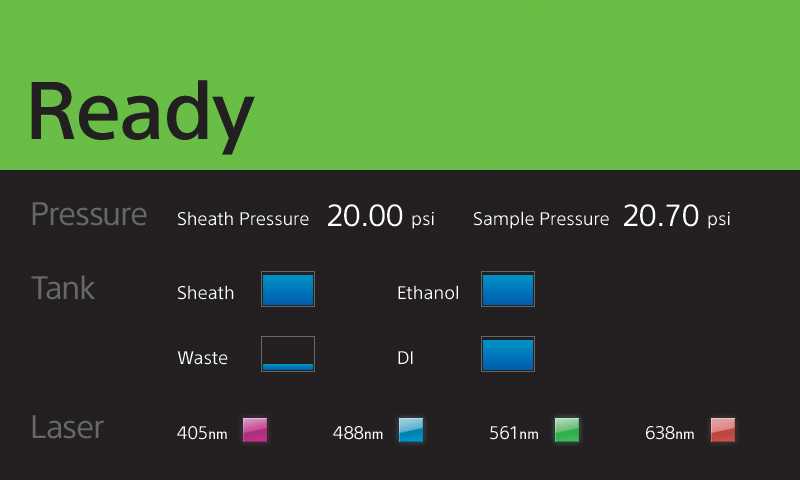

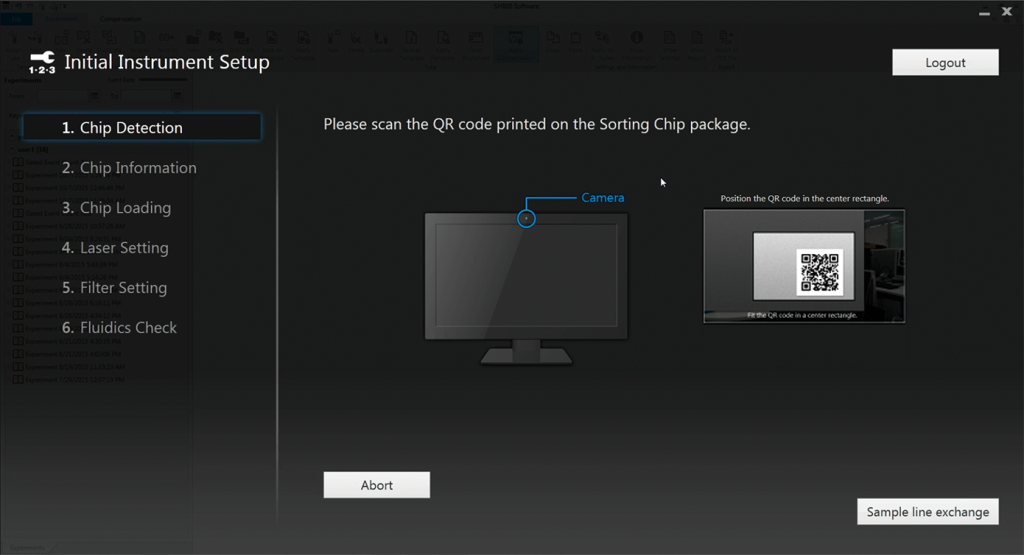

System Startup

Upon start up, the system initialization includes diagnostics that ensure all subsystems are properly working. Once verified, the system status and a green ready message are displayed on the LCD monitor on the front of the instrument.

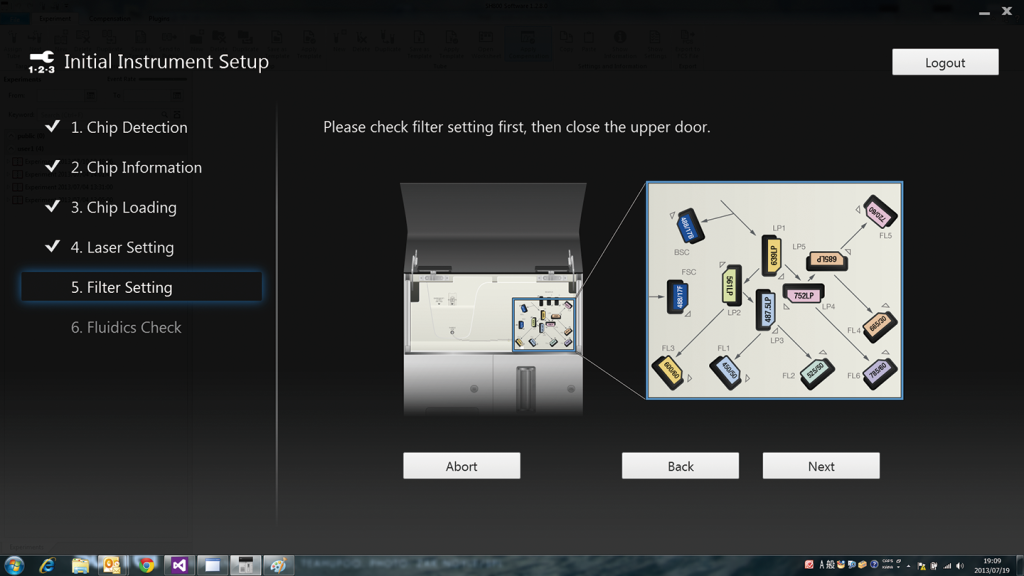

System Startup

The set up wizard guides researchers through the process of loading a sorting chip, selecting lasers, and inserting the optical filters required.

Fluidics Check

When complete, the fluidics check starts, and sheath fluid droplets appear from the tip of the sample probe. If needed, de-bubble and sample line cleaning wizards can be run. Once complete, the auto calibration screen is displayed.

Alignment and Calibrations

The system automatically and precisely aligns the sorting chip to the lasers, calibrates the droplets, and side streams and estimates the drop delay using AutoSetup beads.

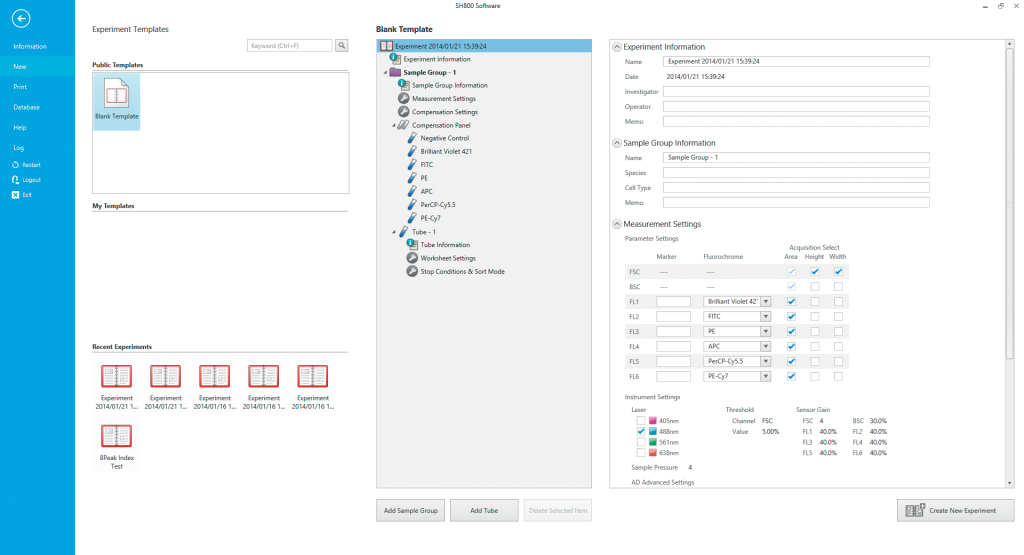

Experiment Settings

Users can create an experiment by selecting a new template, a recent experiment, or a shared template (public) from the Experiment window. If a new template is selected, dialogs guide the user to choose experiment settings such as sample groups, tubes, and pulse parameters for data acquisition. Once a template is selected, the user can start the acquisition or compensation wizard.

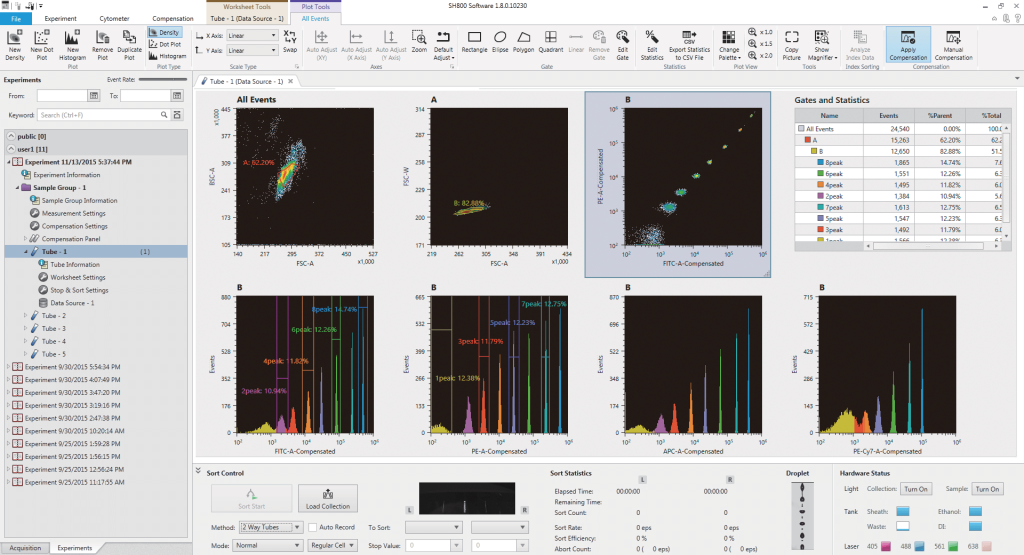

Data Analysis and Display

Data is displayed as dot plots and histograms on worksheets, and events can be marked using gates. The software has a number of tools to select, adjust, label, and measure statistics of target populations. Data can be easily exported as FCS formats (3.0 or 3.1 ) to use with third party analysis software.

Sorting

Once events are gated on plots, targeted cells can be sorted for further analysis. Sort control is managed in a simple dialog where settings and configurations are selected. The SH800S supports a variety of sorting methods and vessels including 2-way tubes, 8-well strips, slides, and 6-, 12-, 24-, 48-, 96- and 384-well plates.

The system supports eight sorting modes to provide different levels of purity (including single-cell mode) and yield to enable optimal results. In addition, the software provides an assisted mode for large cells to improve sorting performance. Three sorting chip sizes (70 μm, 100 μm and 130 μm) are available to accommodate a range of cell sizes and applications.

System Maintenance

The SH800S software uses wizards to guide users to perform routine tasks such as fluidics cleaning for aseptic sorting and parts maintenance.

Options

Biosafety Cabinet

The BCC300AMS Class II biosafety cabinet custom designed for SH800S by the Baker Company is available as an option to provide personnel and product protection. The cabinet measures 118 cm (W) x 99.1 cm (D) x 224 cm (H).

Biosafety Safety Standards Compliance

The cabinet was tested by The Baker Company using microbiological assays with the SH800S sorter inside the work area. The testing concluded that the biosafety cabinet with the SH800S inside met several international biosafety standards including the National Sanitation Foundation Standard 49 (NSF49), and the European Standard 12469.

Built-in Aerosol Management

The cabinet incorporates a built-in aerosol management system which operates independently to actively evacuate aerosols from the sort collection chamber. The dual routes of aerosol evacuation ensure maximum personnel protection.

E-Beam Sterilized Consumables

For applications in which cross-contamination between samples or external biological entities are a factor, optional e-beam sterilized consumables including chip, setup beads, and sample lines can be used to streamline workflow.

Exchangable Sample Fluidics

The SH800S sorting chip is an integrated flow cell/nozzle assembly. It contains microfluidic channels for controlling the flow of sample and sheath fluid. Within the chip, the sample is interrogated by the lasers before it passes through the nozzle for sorting.

Easy Installation

Chip installation and removal are quick and easy to reduce the downtime associated with changing nozzles during setup and removal of clogs. The chip and the PEEK sample line-chip connector assembly, which come in contact with the sample, are fully disposable. This gives researchers the option to change out the sample fluidics path if needed.

Versatile Application Support

The SH800S offers 70 μm, 100 μm and 130 μm microfluidic sorting chips to permit the sorting of a wide range of cell sizes and applications.

Sort Deposition System

The optional Sort Deposition System facilitates high-throughput sorting and precise deposition of cells into 6-, 12-, 24-, 48-, 96- and 384-well plates or PCR plates.

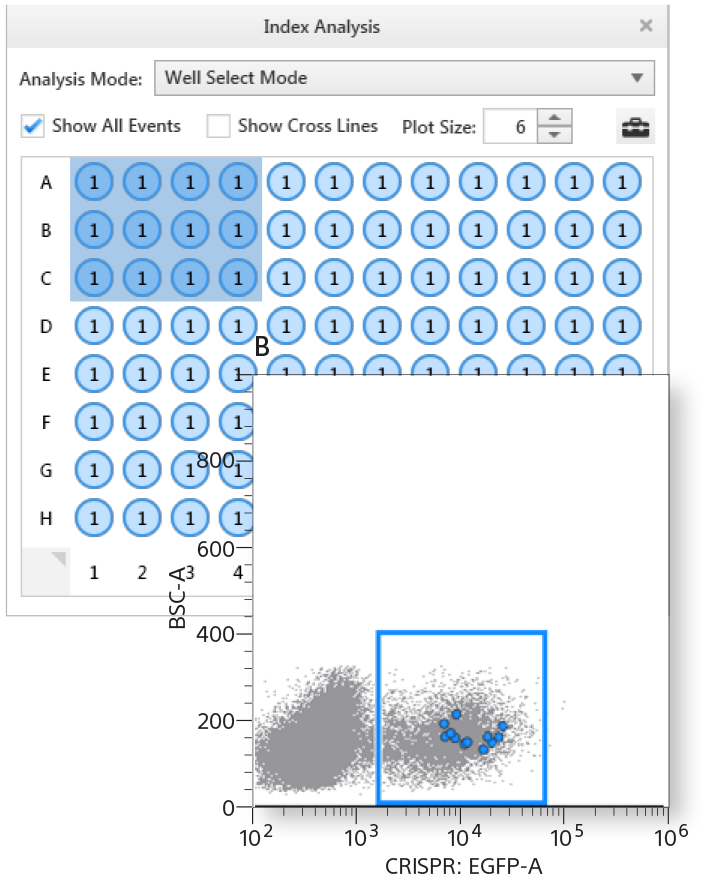

Index Sorting Software

Index sorting software records the X and Y coordinates of each event sorted into a multi-well device. This feature allows researchers to track the scatter and fluorescence intensity of individual cells sorted in each well.

Application

Source: sonybiotecnology.com