Cell Sorters

- Home

- Cell Sorters

- MA900 Multi Application Cell Sorter

MA900 Multi Application Cell Sorter

Overview

The MA900 from Sony meets the needs of most sorting applications, supporting 12 fluorescence parameters and 4-way sorting

Up to 14 parameters from 4 lasers

Automation across the workflow

Easy to learn and use

The MA900 software guides operation. Advanced controls enable customization, and powerful tools let you focus on the biology, not the cytometer.

For Research Use Only.

Class 1 Laser Product.

Automation

Startup automation ensures optimal daily alignment of the chip to lasers

With the highest level of automation available on any cell sorter, the MA900 uses sensors, software, and engineering know-how across the workflow from startup to aseptic cleaning, QC, and sort setup. Intelligent automation dramatically simplifies operation and streamlines troubleshooting.

Initiation

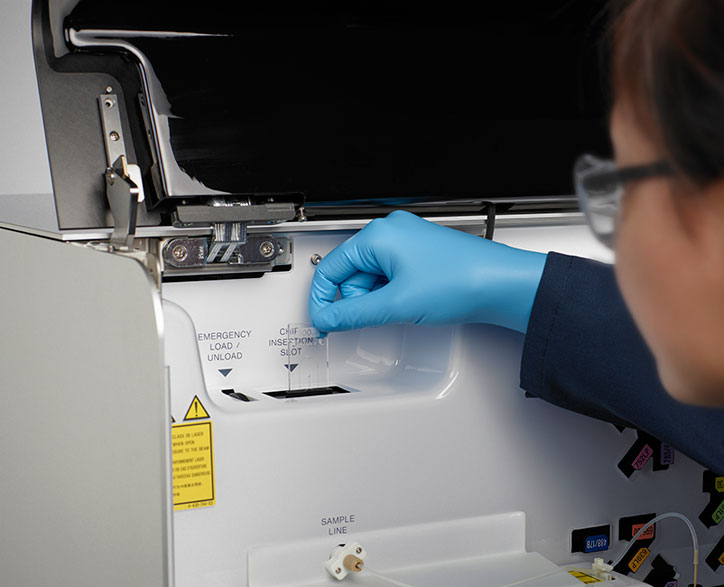

Automated Chip Loading and Positioning

System setup begins with a one-touch installation to load the microfluidic flow cell chip. A setup software wizard guides you through the process of loading a sorting chip, selecting lasers, and inserting the optical filters required. Actuators ensure precise positioning of the chip inside the chip loader. The microfluidic sorting chip uses patented CoreFinder™ technology to automate and streamline key steps in the workflow including chip alignment and accurate calculation of the laser delay, drop delay, side stream angle, and breakoff position.

Once the chip is loaded, the fluidics check starts, and sheath, sample, and vacuum lines connect and seal automatically to their respective ports.

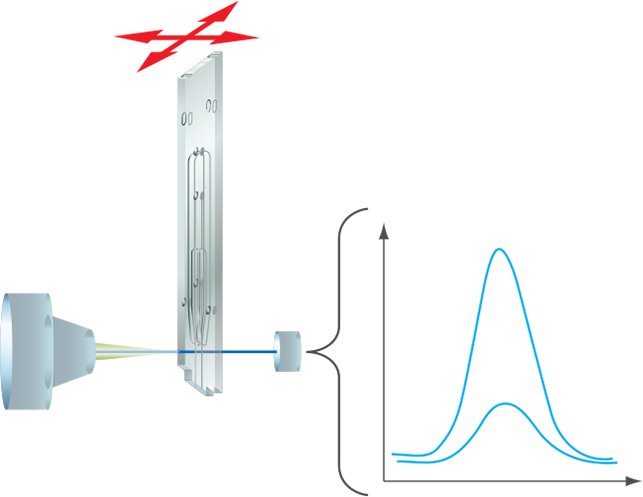

Automated Optical Axis Adjustment

The alignment of the chip to the lasers is optimized automatically using patented technology. AutoSetup beads are used daily to adjust the X and Z position of the chip to ensure consistent results.

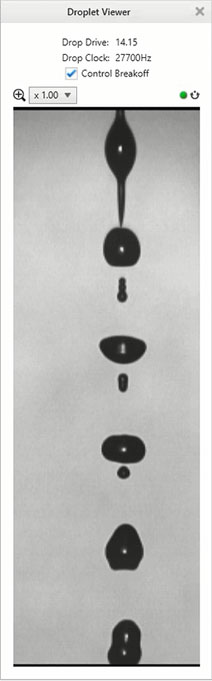

Automated Droplet Calibration

The droplets are automatically calibrated by adjusting the frequency and the drop drive to achieve an optimal breakoff point (BOP) for the 70-μm, 100-μm, and 130-μm sorting chips.

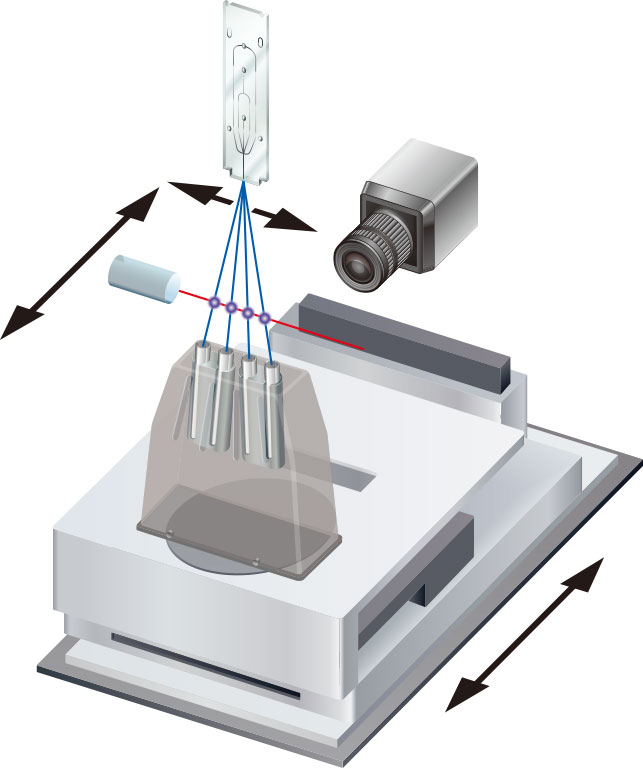

Automated Side Stream Calibration

The angle and the position of the side streams are calculated and adjusted during setup for tube and plate sorting. This ensures that the sort stream is centered in the collection tube automatically.

Automated Drop Delay Calibration

A dedicated laser and camera perform real-time analysis of droplet images using AutoSetup beads. Patented technologies calculate drop delay to enable precise targeting and high yield.

Automated Quality Control

Using QC beads, the rCV and linearity are measured and can be displayed in Levey-Jennings plots. This information helps administrators accurately assess optical performance over time.

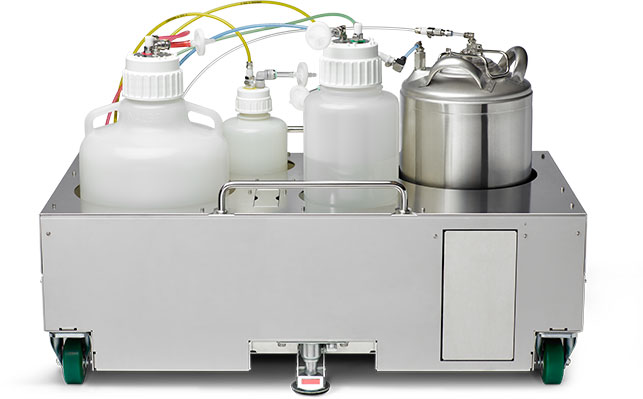

Automated Fluid Sensing

The fluidics cart houses autoclavable sheath, deionized water, and waste tanks as well as tanks containing bleach and ethanol. Weighted sensors on the fluidics cart allow a real-time measurement of the fluid levels, which is displayed in the software.

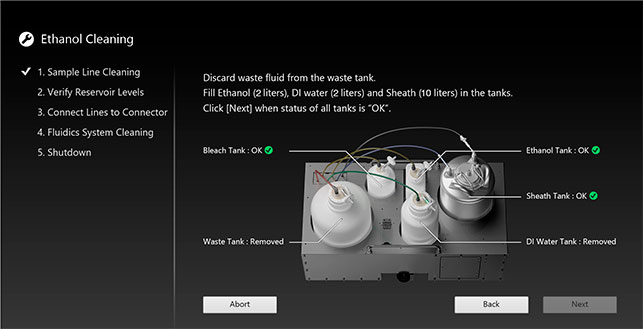

Wizard-Driven Cleaning Cycle

Software guides the operation of default and custom fluidic system cleaning. Default cycles include cleaning with bleach or ethanol. Software guides you through each step of the selected cleaning cycle. Fluid is pumped from three cleaning tanks via a cleaning chip. The software also supports user-defined protocols for setting the time for cleaning. In addition, cleaning reminders can be set up by administrators for convenience.

Sorting

Sorting that adapts to your needs with default and custom sort modes as well as 4-way sorting

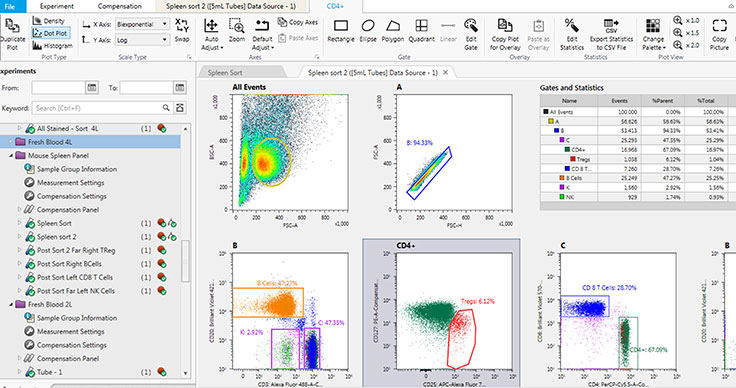

Once events are gated on plots, target cells can be sorted for further analysis. Sort mode, sort gates, and sort devices can be assigned using a simple dialog box. A choice of eight default and five custom sort modes is available to achieve the desired purity and yield of the sorted population. Sort devices supported include 2-way and 4-way tubes as well as 6-, 12-, 24-, 48-, 96-, and 384-well plates.

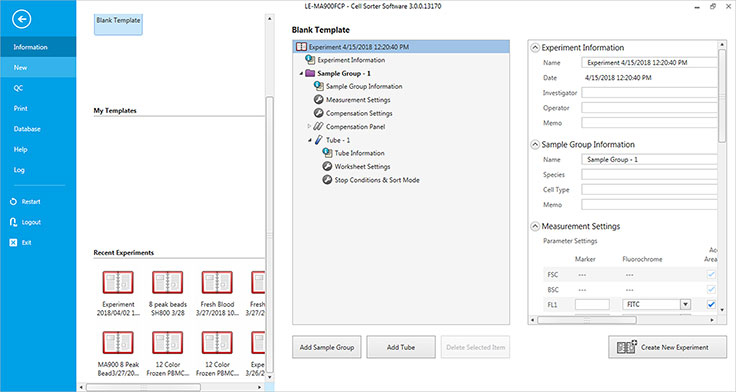

Experiment Settings

Experiments can be created by selecting a new template, a recent experiment, or a shared template (public) from the experiment window. If a new template is selected, the software guides you through choosing experiment settings such as sample groups, tubes, and pulse parameters for data acquisition. Once a template is selected or created, compensation data can be acquired easily by using the software based compensation wizard. Alternatively, uncompensated populations can be adjusted using the drag and drop feature in the software.

Data Display and Using Gates

During acquisition, data is displayed on worksheets as dot plots and histograms. Events in the plots can be marked using gates. A variety of tools are provided to select, adjust, label, and measure statistics of target populations. Once acquired, data can be easily exported as FCS formats to use with third party analysis software.

Automated Sort Monitoring

The software monitors and actively makes adjustments to the drop drive to maintain a stable breakoff point. This feature ensures consistently good sort performance, facilitates walk-away operation, and allows detection of clogs and empty tubes.

Sort Deposition System

The Sort Deposition System is an optional hardware feature that facilitates high-throughput sorting and precise deposition of cells into 6-, 12-, 24-, 48-, 96-, and 384-well plates or PCR plates. Several features on the MA900 enable deposition of single cells at a high efficiency. These include the ability to precisely adjust the position of a plate, assign the center of the drop relative to the target cell position, and utilize custom angled plate holders for multiwell PCR and 384-well plates.

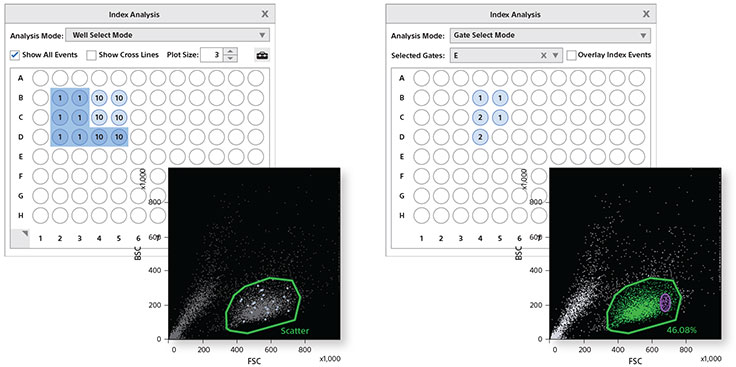

Index Sorting Software

Index sorting software records the X and Y coordinates of each event sorted into a multiwell device. This very precise and easy to use software brings powerful capabilities to research, enabling you to track the scatter and fluorescence intensity of individual cells sorted in each well.

After the sort, the index file can be exported in CSV format or analyzed on the cell sorter. The Well Select feature lets you choose a well and display event(s) sorted in that well on bivariate plots and histograms. The Gate Select feature lets you display the location of events on a plate map based on a selected gate.

These index sort options allow you to perform meta-analysis of data for several applications. For example, clonal variability can be studied based on the expression levels of the fluorescent protein or surface markers. Also, researchers can integrate phenotypic data with mRNA expression analysis of the sorted cells.

Application

Options

If desired, the MA900 can be installed inside an optional custom class A2 level II biosafety cabinet for protection for personnel and products. The custom biosafety cabinets offered by Sony Biotechnology are designed and tested by their manufacturers using microbiological assays with the MA900 in the work area. The cabinets meet international standards including the National Sanitation Foundation Standard 49 (NSF49) and the European Standard 12469.

The cabinets incorporate a built-in aerosol management system which operates independently to actively evacuate aerosols from the sort collection chamber. The dual routes of aerosol evacuation maximize protection.

Download

Source: sonybiotecnology.com